Physical damage or contamination on air data system probe

Effectivity: Global 7500 aircraft

ATA: 34-11

By: Ying Tian – Avionics, Technical Services, Global Series Some operators of in-service Global 7500 aircraft have reported physical damage or contamination on the air data system probe (ADSP) on the aircraft.

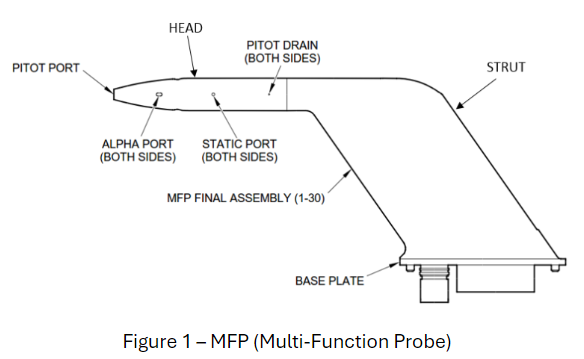

Examples include a dented lip on the pitot port, nose flat damage on the tip, damage on the edge of the angle of attack (AOA) port (also called Alpha ports), or contamination in the ports. See the multi-function probe (MFP), Figure 1. This damage or contamination may cause faulty altimetry or AOA issues during flight and lead to unscheduled removal of the ADSP.

The performance and/or airworthiness of the ADSP may be affected, depending on the extent of the damage. It is important to take extreme care when handling the ADSP units.

Below are some recommendations:

Verify the aircraft configuration during maintenance for ADSP where applicable heater circuit breakers are open. (Ref. AMP BD700-AJ12-00-00-01AAA-398A-A)

Utilize damage prevention cover

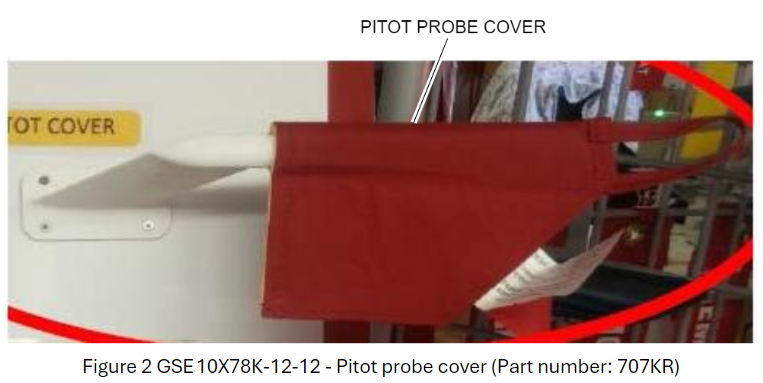

GSE 10X78K-12-12 - Pitot probe cover. Vendor Kinnear Rembourrage, part number: 707KR, see Figure 2.

Covers and plugs Install Procedure (Ref. GHSIP BD700-A-J10-12-00-00AAA-720A- caution). Be careful when you do maintenance on or near the ADSP. The pitot tip, ports, and body of the MFP are sensitive to damage and contamination. Be sure to use only approved covers to prevent damage/contamination. If you do not obey these precautions, damage to equipment can occur.

Exercise extreme caution when installing/removing pressure test fittings on the ADSP

During removal or installation, manipulate the ADSP with care

Do not rest on the ADSP

During return to service, and before flight, check all four ADSPs for cleanliness and general condition

Slight surface damage or discoloration of the ADSP may not necessarily require replacement, especially if no in-flight discrepancy is reported. To assist technicians, we are currently developing an aircraft maintenance procedure (AMP) inspection. It will provide acceptance criteria for dents, scratches near/in/around the pitot port, static ports and drains.

In the interim, if assistance is required to establish ADSP serviceability or for troubleshooting altimetry (Altitude-Speed) or AOA issues, please contact the Customer Response Centre (CRC).